Good potential in this year’s maize crops looks set to give dairy farmers an opportunity to clamp decent tonnages of quality silage, which could provide a useful buffer with uncertain milk prices, says Volac silage expert, Ken Stroud.

But it will be crucial to avoid common harvest pitfalls that let dry matter (DM) and nutrients slip away in the clamp.

"We're seeing a fair bit of uncertainty in milk prices," says Mr Stroud. "Also in cereal prices, which could impact on feed costs.

"While some maize crops haven't fully recovered from the dry spring, most look in good shape. Conserving good stocks of quality silage, to become more self-sufficient in winter feed and maximise milk produced from homegrown forage, makes sound financial sense in times of volatility," he adds.

Typically, about 1 in every 10 trailer loads of maize DM ensiled are lost due to unwanted bacteria, yeasts and moulds growing in clamps, says Mr Stroud, but losses can double if attention to detail slips at harvest and ensiling. Also, these microbes consume the most nutritious parts - sugars and starches - leaving the remaining silage lower in energy, he stresses.

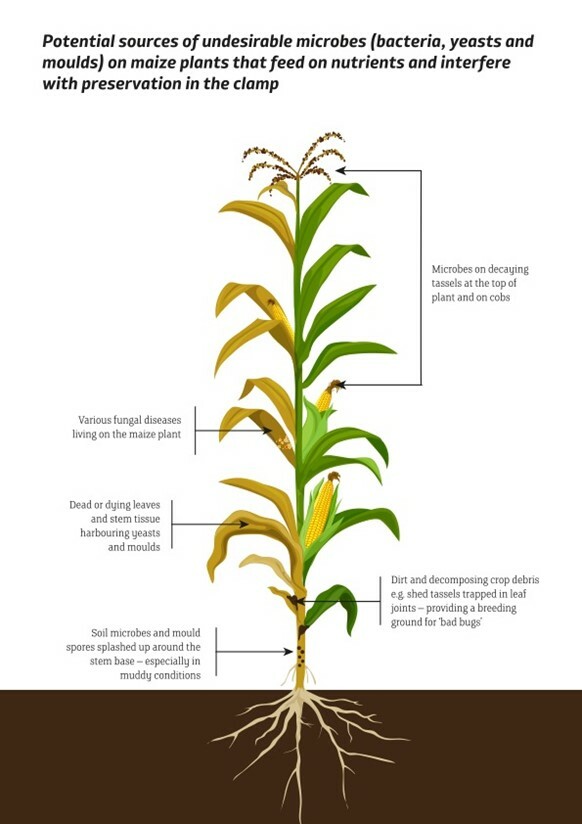

"Unwanted microbes come into the clamp on the crop at harvest (see infographic). You can't completely stop this, but inhibiting their growth in the clamp is vital. This requires attention to detail at several stages (see table). All these stages are important. But there are three common pitfalls that could be particularly important to avoid this year."

Pitfall 1 - harvesting maize too late

Harvesting maize late, when it is dying back, not only risks the crop being past its nutritional peak, says Mr Stroud, it also increases the risk of unwanted microbes coming into the clamp on the dying foliage.

"Too often maize is harvested when leaves are dying or dead. It should be harvested as soon as it reaches 30-33% DM and ideally while still green. Doing this provides a good balance of starch in the cobs and living foliage with higher nutritional value. Crops harvested drier are also harder to consolidate, leaving them prone to losses from heating caused by aerobic spoilage," he adds.

Pitfall 2 - thinking maize ‘conserves itself'

A common myth is that maize does not benefit from conserving with a silage additive,

says Mr Stroud. But after investing in growing the crop, ensiling it untreated leaves its conservation at the mercy of whatever microbes are present on the crop - good ones and bad ones, he adds.

"Maize silage suffers two types of losses: obvious losses from heating, caused by yeasts and moulds growing in the presence of air; but also invisible losses from poor fermentation, due to inefficient fermentation bacteria. Both waste the silage's DM and energy and release carbon dioxide, which is a greenhouse gas.

"You can't regulate which types of bacteria, yeasts and moulds are present at harvest. But applying a dual-acting additive, such as Ecocool, containing beneficial bacteria effective against both problems, drives in favour of a quality fermentation to put you in better control. Ecocool has also been shown to keep maize silage cool and stable for more than 10 days after exposure to air."

Pitfall 3 - harvesting maize too low

Although tempting to cut maize low to the ground - especially if looking for extra bulk - the stem base is low in nutritional value and typically higher in unwanted microbes, says Mr Stroud, so you risk losing more than you gain.

"Instead, ask your contractor to leave at least 15 cm of stubble. Similarly, make sure they chop the crop short enough to aid consolidation, especially with drier crops, but long enough for it to perform in the cow's rumen. Consider a 1.5-2.0cm chop length, or 1.2cm if needed," he suggests.

Tips for better maize silage

|

Tip |

Reason |

|

Clean the clamp before harvest |

To remove undesirable bacteria, yeasts and moulds surviving on old silage and in cracks |

|

Harvest maize promptly at 30-33% dry matter (DM) |

To provide a balance of:

|

|

Leave at least 15cm of stubble |

Because the stem base is:

|

|

Chop to the optimum length (e.g. 1.5-2.0cm) |

So the maize is:

|

|

Treat with a dual-acting additive |

|

|

Fill the clamp in maximum 15cm layers, roll with sufficient weight and sheet thoroughly (side sheets, an O2 barrier film & well-weighted top sheet) |

(Typically, maize at 30% DM requires 25% of its weight arriving at the clamp/hour to consolidate it. So 100 tonnes/hour requires 25 tonnes rolling constantly) |

Source: Volac

This post is funded by Volac.